LogiCell® Carts Systems

QUICK START GUIDE

Set-Up & Use

Unpack Your New LogiCell® Carts

Inspection:

- Receiving area must meet all State and Local regulations prior to unpacking

- Customer must inspect both the skid and Cart before and after unpacking to determine if any items were damaged during shipping

- All damaged items must be listed on the Bill of Lading

- Customer is responsible for the proper disposal of all packing materials; the disposal of these items must meet all State and Local regulations

Unpacking LogiCell® Carts

- LogiCell Carts are shipped on well-constructed wooden skids.

- Two (2) steel bands secure the product(s) to the skid. The surfaces of the Carts are protected by layers of plastic wrapping.

- Care must be taken while unpacking the items to avoid damage. Do not drop tools on the Carts or scratch the surfaces with sharp edges.

- Retain all shipping materials until the items are completely unpacked and inspected for damage.

IMPORTANT: Wear gloves and eyewear during the unpacking process.

1. Use tin snips to cut the metal bands holding the Cart to the wooden skid

2. Remove Packing Slip from Protective Wrap for receiving purposes

3. Remove Protective Wrap with utility knife from around cart

NOTE: If using a utility knife, be careful to avoid scratching the cart

4. Remove foam blocks from between casters

5. If you have received Glass Door Models, remove the shipping foam from between the doors

6. Set provided Ramp down with tallest edge flush to the pallet

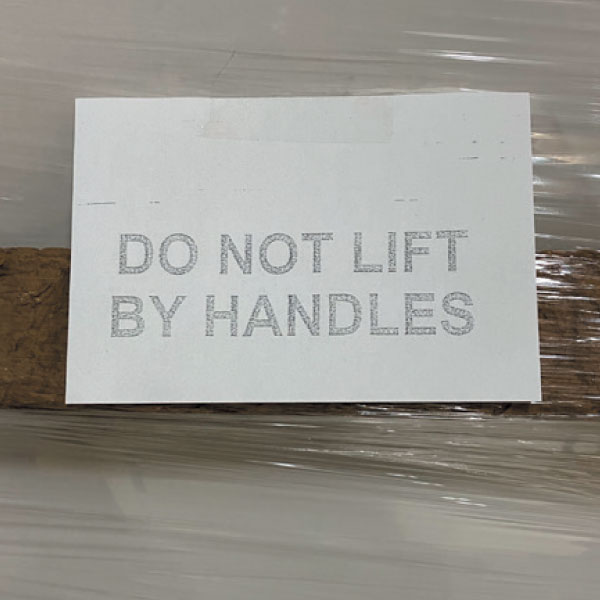

7. Carefully roll cart down ramp; do not lift by the handles

8. Discard shipping and packing materials in compliance with state and local regulations

9. LogiCell Carts must NEVER be double stacked

Unlock Your New LogiCell® Carts

Key Lock

LogiCell Key Lock Carts are shipped unlocked.

Keys can be found in your Welcome Packet located inside your LogiCell Cart.

eLock

The eLock system on your LogiCell Carts has a 10 button keypad with a # button located behind the lever when in the locked position. This keypad comes with a preset access code (2244) and preset master code (11335577).

To access your eLock LogiCell Cart for the first time, simply punch in 2244 and turn the lever to the right.

- Open Lock using Access Code 2244

- Enter #11335577

- Enter 02

- Enter New Access Code (New Access Code is 4 digits)

- Open Lock using Master Code 11335577

- Enter #11335577

- Enter 01

- Enter NEW Master Code (New Master Code is 8 digits)

- Enter NEW Master Code AGAIN

NOTE: Make sure to document your new eLock access and/or master codes in a secure location.

Clean Your New LogiCell® Carts

- Always comply with facility cleaning standards and guidelines*.

- Before using any cleaner, do a spot test on a small, inconspicuous area of your product to ensure it will not cause damage to the finish.

- Solvents, acidic or abrasive cleaners can damage surfaces and are not recommended.

- Wipe spill away promptly and rinse several times with water.

- Steel wool and other abrasive cleaning pads will damage the surface.

- Do not mix different cleaning agents to clean or disinfect.

- Rust remover, drain cleaners and toilet bowl cleaners contain harsh chemicals and will quickly cause permanent damage.

- Hair, textile and food dyes can cause permanent stains.

Recommended Cleaning Products

Soap and water and most common cleaners/disinfectants are excellent for most cleaning and disinfecting purposes as long as the directions on the label are followed.

The following cleaning products are acceptable when used according to directions:

•AHP Accel®

•Bleach Mixture (1/3 cup bleach per 1 gallon of water)

•Dispatch® Hospital Cleaner Disinfectant

•Diversey™ Oxivir® Tb Wipes

•Hydrogen Peroxide

•Isopropyl Alcohol

•Metrex™ CaviWipes™

•Oxivir® Tb

•Quaternary Cleaners

•Sani-Cloth® AF3

•Sani-Cloth® HB

•Sanimaster™ 6

•Super Sani-Cloth®

Recommended Cleaning Procedures

- Remove debris before application of the cleaner/disinfectant.

- Apply cleaner/disinfectant according to the label. Avoid using sprays on products with electronic components.

- Ensure that the solution is wiped away with a clean cloth. Do not allow the cleaner to remain on product longer that the time recommended on the label.

- When solutions are NOT contained in a spray bottle make sure to appropriately dispose of the solution, cleaning cloth and cleaning supplies after each cleaning.

For troubleshooting, help, and FAQs for LogiCell® Carts, CLICK BELOW.

For helpful, how-to videos for LogiCell® Carts, CLICK BELOW.

Accessories for LogiCell® Systems

Click the + signs below and hit play to view demos of the LogiQuip LogiCell® Systems Features

Shown:Triple-Wide Two Column Cart