Intelli-Flip™ System

Smart Inventory Management

More Supply Tracking. Less Effort

LogiQuip’s patented Intelli-Flip System is a simple, intuitive tool that automates inventory management, saving you up to 50 minutes per day per PAR location in supply management tasks. Replacing the traditional two-bin system, Intelli-Flip is paired with LogiQuip’s patented Kanban Flippers and wire shelving providing up-to-date inventory management that is managed through a centralized dashboard. This lean, system-driven solution increases productivity and patient satisfaction while reducing labor and costs.

“…the LogiQuip (Intelli-Flip) system is extremely simple and we feel will be a big benefit to our team as well as Nursing….. feedback and benefits of this system were very positive from Nursing and Supply Chain staff….my director is looking to push the system out to all sites in the near future.”

Ben McGlashen, Regional Manager Supply Chain Site Operations

Intelli-Flip™ System Features & Benefits

Simple & Responsive

secure Intelli-Flip Portal

ERP Integration

Access Control

Intelli-Flip Connect

Implementation

Intelli-Flip Optimizes Inventory Management

allowing nurses to focus on Patient Care

Intelli-Flip Portal

Track inventory, velocity trends, days on hand, stock levels, system status updates on Monitor function, and battery life through a secure Dashboard on Intelli-Flip.net. No need to go to the PAR location.

Manage Inventory

Fully automate supply tracking with Intelli-Flip. The Intell-Flip Portal tells you which supplies need to be replenished at each PAR Location without scanning or visiting the PAR locations.

Intelli-Flip Connect

Intelli-Flip Connect is an exclusive feature that allows the system to move to a cellular connection if the Wi-Fi signal is lost. This helps to ensure you never lose information.

ERP Integration

Easily create requisition files to upload into your ERP System for order generation.

Track Product Activity Trends

Track Product Activity Trends and order accordingly based on the data from your Portal.

Monitor Supplies

Monitor which supplies are used most, how many days on hand of supplies, when stock levels dip, and when supplies exceed expected velocity so that you can react accordingly.

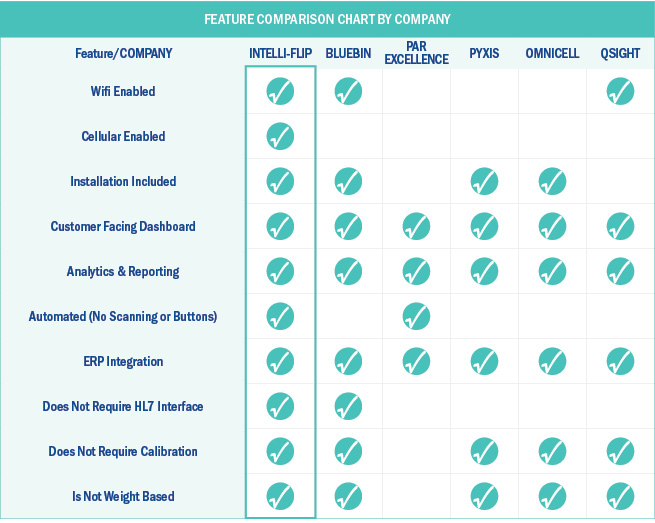

How Does intelli-Flip™ stack up?

There are several options available to help automate inventory management, but Intelli-Flip’s unique systems requires no scanning, no buttons, and no weight calibration. In addition, the Intelli-Flip Dashboard found at Intelli-Flip.net allows you to manage inventory from a singular location. No special software to download. No need to go to the PAR location.

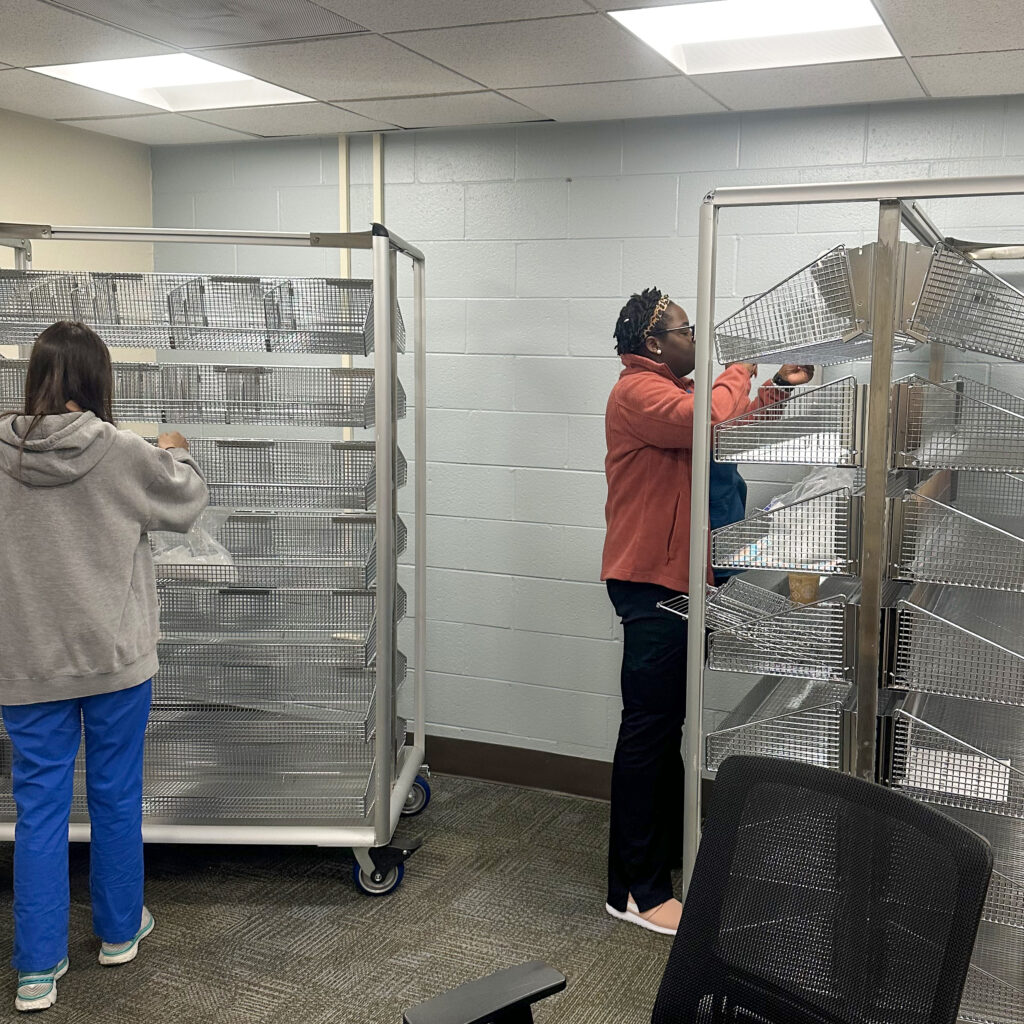

Let Us Do The Heavy Lifting

From your first consult and throughout your day-to-day experience with Intelli-Flip, LogiQuip’s Services Team is there. Our experienced Staff will work with you to review your existing layout and PAR levels, implement the final solution, and train your staff, making this a turnkey solution that will help to ensure you have the supplies you need when you need them.

Review Existing Layout

And PAR Levels

Obtain PAR Lists

Review Floor Plans

Cart Layouts and Photos

Work with Staff to Determine Issues to Address

Implement New Design

Build out Shelving units

Install Intelli-Flip Monitors and assign them to products

Install data consolidator and connect to Intelli-Flip.net

Train Staff

Train System Administrator

Train Department Staff

Train Nursing Staff

Product Integration

Intelli-Flip integrates with our existing ParWall® , ParWire® , and LQS Wire Shelving lines and Kanban Dividers for easy installation. Once Intelli-Flip is installed, inventory levels for all supply locations using Intell-Flip can be viewed and managed from a personalized dashboard on Intelli-Flip.net.

Expert Advice, Tips, and Tricks

In the following Beyond Clean Expert Series™ posts, our very own Dustin Patterson outlines a mix of best practices, Lean principles, and healthcare storage options for Sterile Processing Departments and beyond.

Contact Us

Call 800-665-3760

Email [email protected]