Success Story

Pittsburgh, PA

Through our tailored approach, we saved the customer 20% and freed up space for future growth

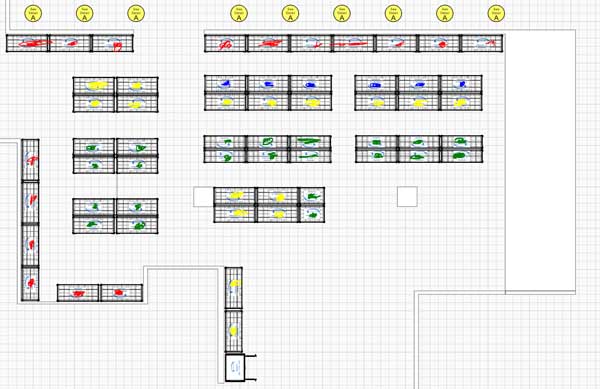

as well as more space in the department to move efficiently. SKU placement was based on the application of that for a procedure. Separated by General, Total Joint, Sports Med, Linen, Generic, and custom packs. We also have provided signs for each cart with the correct category. Recorded the SKU locations and provided them with a master file that is sortable to find items when needed.

See The Difference

Before

After

Before

After

Project Objectives

Contact Us

[email protected]

Key Accomplishments for This Build

Future Growth

61 new carts were installed using the existing footprint. With the optimized organization, 9 of the new carts were left empty for future growth.

Customized Carts

Build carts based on the size of the products and categories

Create a master list

Labeled products and recorded the location of each supply to create a searchable master list

Time Spent on site

3 days on-site to install, convert supplies, label supplies, and recorded supply location for the database.

Scope of work in the Sterile Processing Department

We used a combination of LQS Flat Wire and Basket Shelving, and ParWire Fine Mesh Basket Shelving

Finished Product Gallery