Success Story

NICU, CHARLESTON, SC

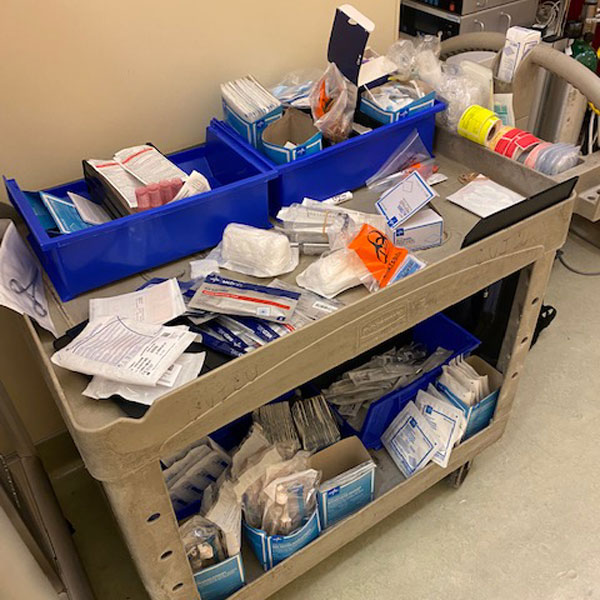

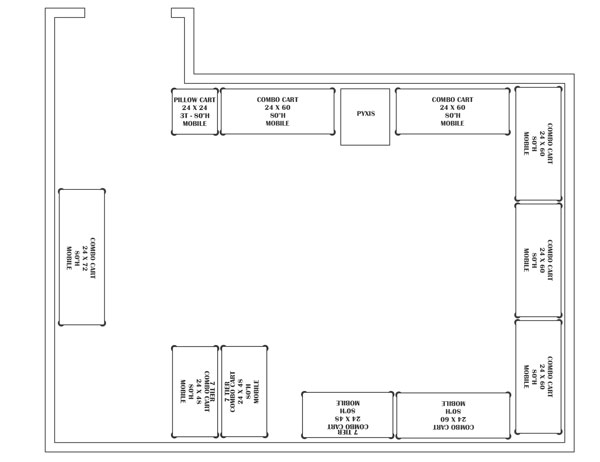

Like so many healthcare facilities, this customer was struggling to do more with less. They are short-staffed and frequently face stockouts of some of their faster-moving supplies, especially over the weekends. Working collaboratively with the NICU Staff we were able to design an efficient, clean Supply Room that set them up for success. Leveraging a mix of Basket Shelving with Dividers, Flat Wire Shelving, and high-density Distribution Carts we addressed some of their core needs while reducing the amount of time spent by their Supply Tech on replenishing supplies.

See The Difference

Project Objectives

Contact Us

[email protected]

Key Accomplishments for This Build

Customized Carts

Build carts based on the size of the products and categories

Reduced Stockouts

By creating “Max Fit” PAR Levels, we were able to nearly eliminate stockouts, even on the weekends when Supply Techs were off-duty, ensuring the Nursing Staff had the supplies they need when they need them.

Saved Supply Tech Time

Labeled products and recorded the location of each supply to create a searchable master list

Time Spent on site

2 days on-site to install with 3 LogiQuip Team Members and 2 hospital employees. All carts were built off-site and sent over to minimize staff interruptions.

Products Used For This Transformation

Leveraging a mix of Basket Shelving with Dividers, Flat Wire Shelving, and high density Distribution Carts we addressed some of their core needs while reducing the amount of time spent by their Supply Tech on replenishing supplies.

Finished Product Gallery